-

30755 steelwise camber web AISC Home

load to dead load, superimposed dead load, and 10% of live load. If one does decide to take superimposed dead load or live load into account, the camber pertaining to this load should not exceed ½". At the 1996 North American Steel Construction Conference, two papers were presented advocating the use of 80% of beam deflection

Get Price -

(PDF) Specific Pressure in Steel Rod Rolling with Grooves

Specific Pressure in Steel Rod Rolling with Grooves Article (PDF Available) in Journal of Materials Engineering and Performance 14(3):378382 · June 2005 with 347 Reads How we measure 'reads'

Get Price -

Deformation Processing Drawing

Prof. Ramesh Singh, Notes by Dr. Singh/ Dr. Colton 34 Example Problem Assuming zero redundant work and frictional work to be 20% of the ideal work, derive an expression for the maximum reduction

Get Price -

Channel Weight Calculator / ismc channel weight ...

Channel Weight Calculator, channel weight calculation formula, ms channel weight calculation formula, ismc channel weight calculation formula, c channel weight calculation formula, steel channel weight calculation formula, ss channel weight calculation formula

Get Price -

load of iron ore on conveyor belt design

iron ore conveyor systems design – Grinding Mill China. iron ore conveyor systems design. iron ore conveyor system manual iron ore processing plants star trace offers turnkey solutions for iron ore load of iron ore on conveyor belt design... OBTENIR UN PRIX

Get Price -

Solved: 2. Consider A Sheet Of Metal Of 5in. Width And 0 ...

It is to be hot rolled to a thickness of in. in one pass using a mill whose steel rolls are of 10in. diameter; the value of u om this case is about, and the planestrain flow stress of the metal sheet is 100 ksi. a) (Ipt.) Calculate the rolling load, if roll flattening is ignored. b) (2pts.)

Get Price -

Structural Studs | ClarkDietrich Building Systems

The load/span tables that are in this lookup tool are based on service level (ASD) wind loads. Therefore, to properly use the load/span tables in this tool, multiply the IBC 2012/ASCE 710 design wind pressures by (reference section ASCE 710) prior to entering the load/span tables. Example:

Get Price -

Cambering Steel Beams

coldworked steel and a raising of the proportionallimit stress, as a result of the aforementioned aging or application of mild heat. Two facts emerge from this brief discussion of cold bending: 1. The same allowable stresses (or load factors) can be applied to coldcambered beams as to uncambered beams, provided that they are allowed to

Get Price -

Coil Sheet Calculators | Steel Warehouse

Explore Our Available Steel Products Grades . Our knowledge and experience give nearly 100% accurate delivery of High Carbon, Low Carbon, Stainless Steel products processed and packaged to your exact specifications.

Get Price -

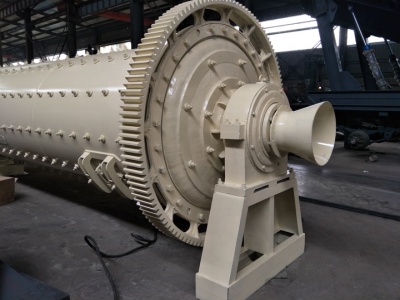

Rolling Mill an overview | ScienceDirect Topics

The next lower level of control, level 2, is known as process automation, where each product is rolled and tracked individually in the plant. This function also contains mathematical models which calculate the optimum rolling setups for the mill ( gap, speed, force, temperatures).

Get Price -

Tube Calculator Rogue Fabrication

This calculator is intended to help aid in the design process, which must be carried out by a trained professional. Any information provided by Rogue Fabrication, LLC, is not an acceptable substitution for professional analysis or a promise or certification of the performance of any material or design.

Get Price -

Structural and Plate Steel Terms Definitions | Engineers Edge

SHEET STEEL: Either hot or cold rolled sheets produced on continuous sheet mill where the minimum width produced is 24. Sheet coils when slit to narrower widths is called slit sheet. SHOT BLASTING: Cleaning surface of metal by air blast, using metal shot as an abrasive.

Get Price -

Hot Cold Working and the Rolling Process

Hot Cold Working and the Rolling Process . Hot Cold Working The distinction between hot working and cold working does not depends solely on the temperature, but rather on the processing temperature with respect to the material recrystallization temperature.

Get Price -

Homework solutions for test 2 Nc State University

Homework solutions for test 2 HW for Lecture 7 What is meant by the term faying surface? Answer. The faying surfaces are the contacting surfaces in a welded joint. Define the term fusion weld. Answer. A fusion weld is a weld in which the metal surfaces have been melted in .

Get Price -

Maintenance for productivity Rolling models

Cold rolling mills are an important part of the production of metal sheet. In ... model is used to calculate the passschedule and the mill preset 1. Based on the coil and rolldata, scheduling ... friction variations on the rolling load can be most clearly seen with mild steel and light gauges 3.

Get Price -

All About Steel Cargo Damage More Than Shipping

Dec 18, 2017· Damage can also occur before loading, while the cargo is in storage, or in transit from the mill to the ship. The below listed steel products are commonly shipped by sea. Coldrolled coils: Finished sheet steel in a transportation coil; 2 to 28 ton weights. Hotrolled coils: Sheet steel being transported to a rolling mill; 2 to 28 ton weights.

Get Price -

Simplified hot rolling load calculations incorporating ...

*A 100Kw, 10Kc frequency power source was used to heat the rolls. *A Feed and Northrup Surtemp surface temperature probe was used to measure strip exit and roll surface temperatures. (The speed of response was sec for 90% of a 538 (1000) step range.) Simplified hot rolling load calculations incorporating material strain rates 531 TABLE 2.

Get Price -

Tube Forming Handbook Paumac Tubing

PAUMAC Tube Forming Handbook was designed to be a useful guide for the buyer, engineer or designer whose responsibilities include the specifications and procurement of metal tube assemblies. Sections on bending, end finishing, coating, and tube design provide previously hardtofind information that will help to minimize the cost of your

Get Price -

Hot Rolling Mill Hydraulic Gap Control (HGC) thickness ...

P. Kucsera et al. Hot Rolling Mill HGC Thickness Control Improvement – 96 – Figure 2 Measured mill stretch characteristic When the mill is loaded, the mill stretch force is measured by load cells or calculated from the measured HGC pressure and can be used to calculate the actual mill stretch.

Get Price -

The Art of Metal Roll Bending | Acrotech, Inc.

The reason we are powering the urethane roll is to eliminate any slippage that would be caused by rolling oily material. The urethane roll itself is not affected by grease or oil; therefore, degreasing of the sheet stock is not mandatory. The Two Roll rolling and curving machine is a machine that is aimed at the high production market.

Get Price -

Mechanics of Cold Rolling of Thin Strip IntechOpen

Mechanics of Cold Rolling of Thin Strip 443 where yiw is the vertical deflection of the work roll at element i, gijw (, ) is the influence function for the work roll deflection due to the combined bending and shear forces generated by rolling load, giwf is the influence function for the work roll deflection due to the force generated by the roll bending mechanism, k represents the minimum element

Get Price