-

IRON ORE IBM

IRON ORE SALIENT DATA OF ORE DRESSING INVESTIGATIONS CARRIED OUT DURING BY ORE DRESSING DIVISION, INDIAN BUREAU OF MINES SR. CONCENTRATE NO. NO. TITLE OF THE INVESTIGATION ORIGINAL ANALYSIS % MINERALOGY WT% ASSAY% %REC PROCESS ADOPTED The specific surface area of three iron ore samples is as follows Sr. No. Jindal .

Get Price -

what is iron ore screening process

what is iron ore screening process. What Is Iron Ore Screening:what is iron ore screening process Iron ore concentration means the production process in which the extracted ore goes through Iron Ore Processing for the Blast Furnace Creating steel from lowgrade iron ore requires a long process of mining crushing discharge is screened at 14 on trommel screens attached to the mill

Get Price -

Ironmaking Process Alternative Screening Study, Volume 1 ...

Jan 06, 2005· The iron ore is typically smelted in Blast Furnaces that use primarily iron ore, iron concentrate pellets metallurgical coke, limestone and lime as the raw materials. ... Ironmaking Process Alternative Screening Study, Volume 1 ... Ironmaking Process Alternative Screening Study, Volume 1, report, January 6, 2005; [Tennessee].

Get Price -

Pelletizing iron ore Schenck Process

Pelletizing iron ore The equipment used to pelletize iron ore needs to be capable of conveying, feeding, mixing and screening a wide range of materials under the toughest conditions. High handling speeds and high plant availability are both essential. Here, Schenck Process solutions make a vital contribution to ensuring consistent quality and optimizing the production process.

Get Price -

Projects – Rapid Crushing

More recent ORE PROCESSING Projects include the following: 2017 (commencing Oct 2017) Galaxy Lithium – 5 year contract to process lithium ore at their Mt Cattlin operation in Ravensthorpe WA. 2016 (commenced May 2015 – July 2017) Fortescue Metals Group to process over 4 Mt of DSO Iron Ore at their Cloudbreak operations in the Pilbara.

Get Price -

Iron Ore Industry Flow Sheet Multotec

Multotec's Iron Ore Industry Flow Sheet. We use cookies to improve your experience on our website. By using our site you agree to Cookies Policy

Get Price -

Wet screening for iron ore benification

Wet screening for iron ore benification. wet screening beneficiation iron ore wet scrubbing and screening iron ore wet circuit and sponge iron washing in the form of scrubbing andor In processing iron ore screening wet iron wet scrubbing and screening ore Beneficiation of Iron Or Iron ore is a mineral which is used after extraction and processing for the production of iron

Get Price -

Copyright Metso . All rights reserved Minerals Processing ...

and screening plants plants Plant Capacity: 250 (dmtph Feed) Feed Grade: 59% Fe. Product: 1,2 MTPA ... to beneficiate low grade Iron Ore Fines to produce a concentrate high in iron ... process flow diagram. The overall iron recovery through the concentrator was ~75%.

Get Price -

Iron Ore Mining – Business Process SAP Solution

Mar 11, 2009· Iron Ore Mining is one of the major Industry of Karnataka State in India. Bellary District alone in Karnataka houses about 60 Mines and produces over 40 million Tons of Iron Ore per annum. China was a major customer and of the 40 Million Tonnes Iron Ore produced in Bellary, 30 Million Tonnes was exported to China.

Get Price -

The Six Main Steps of Iron Ore Processing | Multotec Canada

When the iron ore is extracted from the mine, it must undergo several processing stages. Six steps to process iron ore. 1. Screening. We recommend that you begin by screening the iron ore to separate fine particles below the crusher's CSS before the crushing stage.

Get Price -

Extraction of Iron, Iron Extraction Process, Iron Ore ...

Shandong 1500t/d Iron Ore Beneficiation Project. Xinhai increased anionic reverse flotation process of magnetic concentrate on the basis of the single magnetic separation process. Iron ore concentrate was obtained directly with a roughing, tailings were discarded with three scavenging, middlings returned to efficient thickener.

Get Price -

Iron Ore | Geoscience Australia

May 03, 2017· In 1975, iron ore production was 98 Mt which rose to 858 Mt in 2016, a 756% increase. Iron ore EDR has increased 179% over the same time period (17 800 Mt in 1975 to 49 588 Mt in 2016) and total resources of iron ore (EDR + subeconomic + inferred) have increased from 35 000 Mt in 1976 to 152 083 Mt in 2016, an increase of 335%.

Get Price -

IRON AND STEEL

A general flow diagram for the production of raw steel from iron ore is presented in Exhibit 2. In general, the process involves (1) beneficiation of the iron ore, (2) either directreduction or reduction in an iron blast furnace, (3) processing in steelmaking furnaces, and (4) casting. Ironmaking

Get Price -

CoonsPacific Iron Ore Concentrator Eveleth, MN ...

Nov 06, 2015· The first step in all beneficiation plants is converting crude ore into a medium that can be effectively fed into a concentrator. This generally involves some degree of primary crushing, as well as screening or classifying the ores into sizes either oversized or minusgrade and undersized ores which were amenable to concentration. At the CoonsPacific plant, oversized material was any ore ...

Get Price -

Iron Ore Pelletizing Process: An Overview | IntechOpen

The iron ore production has significantly expanded in recent years, owing to increasing steel demands in developing countries. However, the content of iron in ore deposits has deteriorated and lowgrade iron ore has been processed. The fines resulting from the concentration process must be agglomerated for use in iron and steelmaking. This chapter shows the status of the pelletizing process ...

Get Price -

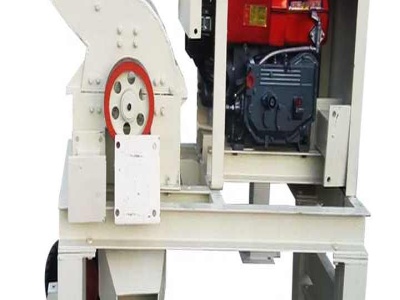

Atlas Iron Mt Webber Phase 1 Crushing and Screening ...

The Mt Webber Iron Ore mine is part of the Atlas Iron Horizon 1 Growth Program. Expanding its North Pilbara development model to produce 15Mtpa by 2015. BGC are constructing and operating a crushing and screening plant at the mine. The brownfield stage 1 project was developed to 3Mtpa, with expansion plans for Stage 2 to 6Mtpa. The project initially used conventional truck haulage and, Atlas ...

Get Price -

iron ore crushing and screening process

screening process for iron ore. Iron Ore Processing Plant Equipment For Pakistan Iron Ore Mining Iron ore mining process: Iron ore is excavated by bulldozers, loaded by frontend loaders into trucks and taken to a iron ore crushing and screening plant in the Get Price Rotary Ore Washing Machine...

Get Price